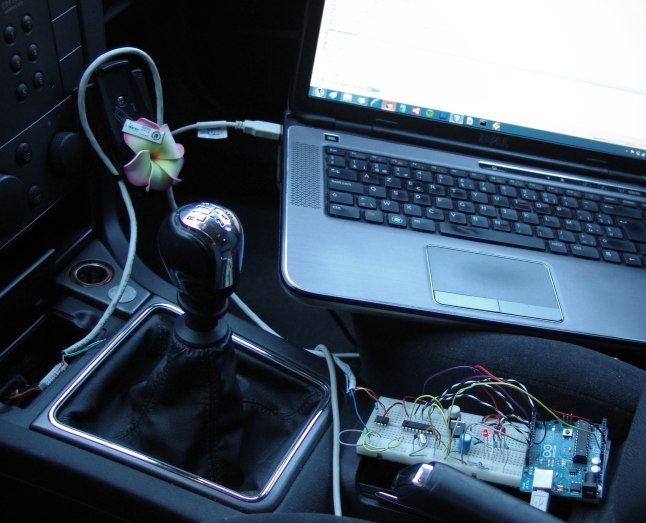

Minor update on the ELM327 OBD scan tool:

A GUI has been added that is auto used when a graphical environment is available, otherwise the program will fall back to console usage. GUI does not contain any usefull controls yet. Users can also force console interface by adding the application launch parameter “-c”. I’ve scanned some of the more convenient PID codes on the Vectra and here and there I’ve also implemented data conversion to make it easy readable. Here is some console output:

PIDS_01_20_SUPPORTED: 01,04,05,0B,0C,0D,0F,10,1C,20,

ERROR: subfunction not supported

ENGINE_LOAD: 0%

ENGINE_COOLANT_TEMP: 25°C

ERROR: subfunction not supported

INTAKE_MANIFOLD_ABSOLUTE_PRESSURE: 100kPa

ENGINE_RPM: 0rpm

VEHICLE_SPEED: 0km/h

ERROR: subfunction not supported

INTAKE_AIR_SENSOR: 30°C

MAF_SENSOR: 0g/s

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

PIDS_21_40_SUPPORTED: 21,23,40,

DISTANCE_SINCE_ERROR_INDICATED: 2660km

FUEL_RAIL_PRESSURE_CT_VACUUM: 0kPa

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

PIDS_41_60_SUPPORTED: 60,

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

PIDS_61_80_SUPPORTED:

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

ERROR: subfunction not supported

The program also comes with auto auto incremented version numbers, this is made through Ant Build tasks. The program version can be checked in a About form.

Furthermore I found more interesting reads:

http://www.canbushack.com/blog/index.php?title=scanning-for-diagnostic-data&more=1&c=1&tb=1&pb=1

https://pcmhacking.net/forums/viewtopic.php?f=3&t=3224&start=350